When I originally started looking for the ideal fireplace screen, I quickly realized that wrought iron options provide unparalleled durability and timeless elegance. After installing and maintaining multiple wrought iron screens in my own houses over the years, I’ve learned what distinguishes high-quality pieces from subpar substitutes. These screens not only provide necessary safety precautions, but they also function as stunning focal points that can transform your entire living environment. In this tutorial, I’ll discuss my experiences with selecting, installing, and maintaining for wrought iron fireplace screens to assist you make the best choice for your home.

Understanding Wrought Iron Quality and Construction

Wrought iron quality varies drastically between manufacturers, as I discovered when my first cheap buy bent after only two seasons. Authentic wrought iron has a very low carbon content, making it flexible and rust-resistant when properly treated. However, many current “wrought iron” screens are actually made of mild steel, which has a similar look but differs in characteristics. I now look for screens with hand-forged parts and traditional joinery processes, as these imply greater quality and durability.

Thickness measurements are more reliable indicators of durability than looks. Quality wrought iron screens have bars that are 1/2 to 3/4 inches thick, which provides excellent heat resistance and structural stability. Thinner materials, typically 1/4 to 3/8 inches thick, may appear identical at first glance, but can warp, flex, or develop stress cracks when heated and cooled repeatedly. I also check the gauge of the metal mesh backing, preferring 16-gauge or heavier for optimal spark protection.

Joinery processes indicate production quality and anticipate long-term performance. Traditional riveted connections and welded joints result in stronger assemblies than simple bolted construction. I carefully scrutinize corner connections, looking for smooth welds with no gaps or visible repair scars. Hand-forged details, such as scrollwork and decorative components, should feel substantial and have subtle flaws to indicate real craftsmanship, as opposed to machine stamping, which creates flawlessly uniform but less durable results.

Selecting the Right Size and Style

Accurately measuring your fireplace opening saves money on returns and guarantees sufficient safety covering. I measure the width and height of the firebox aperture and add 2 to 4 inches on each side to ensure appropriate spark shielding. The screen should be at least 6 inches above the entrance to effectively collect rising embers. Custom size may be required for strangely shaped or arched openings, but many manufacturers have semi-custom solutions that allow for non-standard specifications.

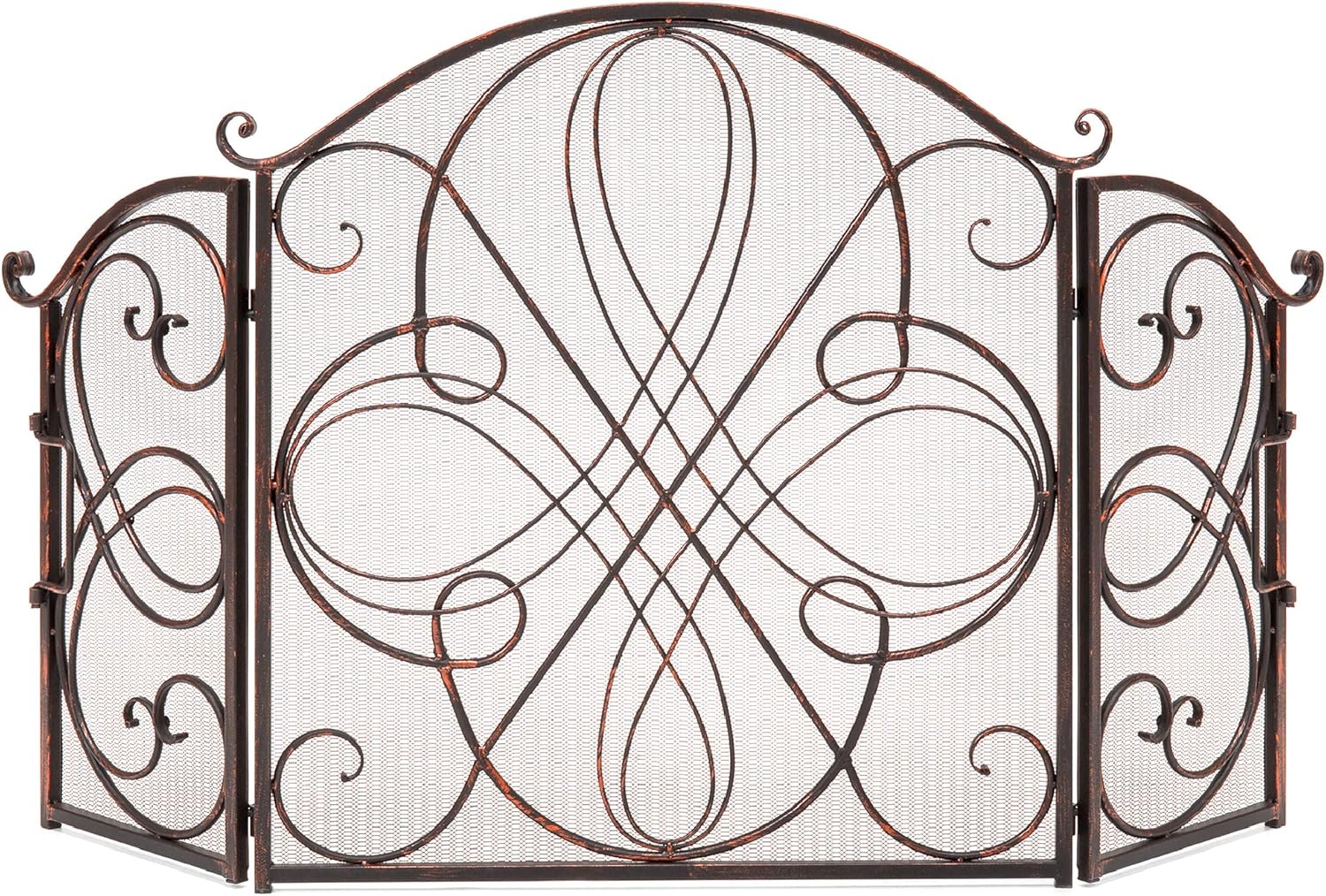

Style selection is determined by both personal desire and current decor, but functionality cannot be sacrificed for appearance. Traditional patterns with simple vertical bars go well with colonial and craftsman decor, while intricate scrollwork looks great in Victorian or Mediterranean settings. I like screens with fewer horizontal features near the bottom, as these regions collect soot and require more frequent cleaning. The choice of finish has a considerable impact on both appearance and maintenance requirements.

Folding screens provide adaptability, but they require stronger hinges to withstand continuous use and heat exposure. Single-panel screens provide the most viewing area but require enough storage space when not in use. Three-panel folding screens, in my experience, provide the optimum balance of utility and ease for the majority of installations. The screen should compliment the materials used to surround your fireplace, such as brick, stone, or tile, to create a coherent appearance that enhances rather than detracts from the overall design.

Installation Procedures and Safety Considerations

Proper installation guarantees the safety and endurance of your wrought iron screen. I always ensure that the screen is snug against the fireplace entrance, with no gaps that could allow sparks to escape. Adjustable feet help create appropriate contact on uneven hearths or somewhat odd apertures. The screen should be stable enough to stay upright if inadvertently bumped, but not so heavy that moving it becomes difficult for routine cleaning and maintenance.

When it comes to arranging fireplace screens, safety clearances are more important than attractiveness. I keep a minimum of 6 inches between the screen and any combustible things such as furniture, drapes, or wall decorations. The screen itself should be far enough away from the firebox to avoid direct flame contact while staying close enough to catch sparks effectively. Depending on the depth and style of your fireplace, this usually entails putting the screen 6 to 12 inches from the opening.

Heat dispersion influences both safety and screen durability. During use, I check the screen temperature to make sure it never gets too hot to touch safely. Proper air circulation around the screen avoids heat buildup, which can deform the metal and pose safety risks. If the screen becomes unusually hot during routine use, it may have been placed too close to the fire, or the fireplace may have draft problems that require professional assessment and repair.

Maintenance and Cleaning Procedures

Regular cleaning keeps wrought iron fireplace screens looking good and functioning properly. During fireplace season, I clean mine once a month with a gentle brush to remove loose soot and dirt, then wipe it off with a moist towel. To remove stubborn buildup, I use gentle soap and water rather than harsh chemicals that could damage protective finishes. The mesh backing requires extra attention since collected material might limit its efficacy at catching sparks and provide a fire risk.

Rust prevention requires continual monitoring, especially in humid regions or coastal places. I inspect the screen on a quarterly basis for signs of rust development, addressing minor spots as soon as possible with fine steel wool and high-temperature touch-up paint. The foot and bottom rails are usually the first to rust due to moisture contact with the hearth. Annually applying a thin coat of high-temperature wax protects exposed metal surfaces from moisture and oxidation.

Seasonal maintenance gets the screen ready for longer use and summer storage. Before storing, I thoroughly clean and apply a little coat of oil to avoid rusting during the humid summer months. I keep screens dry and away from temperature extremes that could cause expansion and contraction stress. Before each fireplace season, I verify all joints, hinges, and mesh areas for damage that may have occurred during storage, and make any necessary repairs before the first usage.

Common Problems and Solutions

Warping is the most prevalent problem I see with wrought iron fireplace screens, which is usually caused by excessive heat exposure or low-quality materials. Minor warping may resolve itself when the metal cools, but persistent distortion necessitates professional repair or replacement. I prevent warping by keeping a safe distance from the fire and preventing sudden temperature swings. Quality screens with heavier metal structure are more resistant to warping than lightweight alternatives that may appear less expensive at first glance.

Rust can form even with good care, especially around welded connections and regions where moisture gathers. I treat surface rust immediately with fine abrasives and high-temperature paint to prevent it from spreading to other locations. Deep rust demands more rigorous treatment, which may jeopardize structural integrity. Prevention by regular cleaning and protective coatings is still more effective than attempting to recover highly corroded screens that have been neglected for a lengthy period.

Folding screens are more susceptible to joint loosening than single-panel designs, which occurs most commonly at hinges and decorative connectors. I check these places on a regular basis and tighten hardware as needed, using tools that will not damage the metal finish. Some loosening is natural as the metal expands and contracts with temperature fluctuations, but excessive movement indicates worn hardware that must be replaced. I have spare bolts and hardware on hand to make rapid fixes and minimize minor issues from becoming large ones.

Choosing Complementary Accessories

Fireplace tools should match your wrought iron screen both functionally and aesthetically. I prefer tool sets built of similar materials and finishes that compliment the screen design without vying for attention. The tool stand should be heavy enough to be stable during use while also not interfering with screen operation. Quality tools with wrought iron handles keep the overall appearance consistent while offering the durability required for regular fireplace maintenance and operation.

Log holders and andirons constructed of matching wrought iron offer a cohesive look that complements the entire fireplace area. I choose items with comparable design features and finishes, although precise matches are not required if the overall style is consistent. The scale should be appropriate for your fireplace size, avoiding huge components that overpower smaller installations or undersized accessories that appear lost in large fireplace openings that require significant visual weight.

Hearth accessories such as wood storage racks and coal scuttles carry the wrought iron pattern throughout the fireplace area. I chose objects that are both functional and aesthetically pleasing. Storage should be adequately designed to meet your fuel requirements and space limits. The trick is to choose accessories that improve practicality while preserving the visual cohesiveness that makes wrought iron fireplace installations so appealing and timeless in their traditional design and practical utility.

How can I tell if my fireplace screen is authentic wrought iron?

Genuine wrought iron feels robust and has minor flaws from hand-forging methods. I evaluate quality by assessing the weight, inspecting joint construction, and looking for classic riveted connections rather than easy welding. Real wrought iron acquires a characteristic patina over time and is more resistant to rust than mild steel substitutes. The price frequently reflects authenticity, as real wrought iron is more expensive due to specialized manufacturing procedures and superior materials that reward the investment over time.

What is the appropriate distance between the screen and the fireplace opening?

To ensure maximum safety and functionality, I leave 6-12 inches between the screen and the fireplace entrance. This spacing eliminates direct flame contact while still providing sufficient spark shielding. Closer placing risks warping from extreme heat, whilst broader distances may allow sparks to escape around the sides. The exact distance is determined on your fireplace’s depth, screen height, and fire size. I change the location based on real use, monitoring the screen temperature to guarantee it remains safe to touch during normal operation without losing protective effectiveness.

How frequently should I clean my wrought iron fireplace screen?

During active fireplace season, I wipe my screen once a month to maintain its attractiveness and safety. Light brushing eliminates loose material regularly, while full washing with light soap is done periodically. Heavy use periods may necessitate more regular care. Between seasons, I provide extensive maintenance such as rust examination and protective treatments. The mesh backing requires extra attention because collected debris diminishes spark-catching ability. Regular cleaning avoids buildup, which becomes difficult to remove and may threaten both safety and attractiveness over time.

Can I remove the rust on my wrought iron screen myself?

Surface rust responds well to DIY treatment using fine steel wool and high-temperature paint suited for fireplaces. I treat minor areas right away to prevent them from spreading. However, extensive rust or structural damage necessitates professional assessment and repair. The idea is to respond fast when rust occurs and use heat-resistant materials. Prevention through frequent cleaning and protective coatings remains more effective than repair attempts, which may not give long-term solutions for severely damaged screens.

Which finish options are ideal for wrought iron fireplace screens?

Matte black finishes hide grime while providing a timeless look that suits most design types. I favor high-temperature paints made expressly for fireplace installations over ordinary finishes that may fail under heat stress. Natural iron treatments develop an appealing patina with time, but they require more maintenance. Decorative finishes, such as bronze or pewter, offer visual character while showing more wear. The finish should match your maintenance preferences and accent existing fireplace hardware to create a unified look that improves rather than detracts from the overall design.

How should I store my fireplace screen throughout the hot months?

Proper storing avoids rust and damage during the off-season. I completely clean before storing, removing any soot or debris that may attract moisture. During humid months, exposed metal surfaces are protected with a light application of oil. I store screens in dry places away from high temperatures, with cloth covers to prevent dust gathering. Folding screens should be stored flat or properly supported to avoid warping. Before each season, I inspect stored screens for damage and make any necessary maintenance to ensure that the fireplace operates safely when it is used again.

Wrought Iron Fireplace ScreensTrinity Stairs

Related Posts: